After setting up your sewing machine, it is now time to thread. Threading is typically a simple and quick process provided if you know the knack of doing it. Though the process seems daunting, believe me, with practice you will be able to thread your machine in no time. During the initial stages, you will consume a lot of time for threading your machine. But don’t worry you will master the techniques soon. It is important to go through the manual before beginning the process. To begin with, understand the basic principles of threading. There are two different thread sources to facilitate sewing.

The spool of thread purchased from shops features above the sewing machine, and this is used to thread the empty bobbin. The bobbin with the thread is fitted below. There is a prong that sticks atop your sewing machine which is termed the spool pin. Position the spool of thread on top of the spool pin. While most spool pins twig outwards, a few remain popped up to the left side. They avail a cover made of plastic to accommodate the spool of thread. The thread comes out through this spool pin to facilitate sewing. Now coming on to the technique to thread the bobbin.

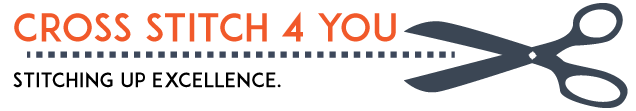

There is a small hole within the bobbin through which the thread is wrapped for quite some times. The thread then unravels from the backside. Make sure to position the bobbin with the thread above the bobbin winder. It has to be secured by flicking the stopper present adjacent to it. It is now time to switch on your machine. It is essential to hold the thread that sticks out from the bobbin for three seconds. Transfer some of the thread from the spool to the bobbin as you press down. You have to keep doing the process until the bobbin is filled with thread.